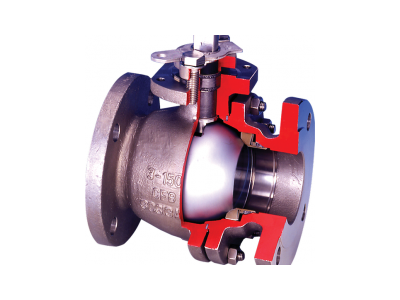

High precision machining results in excellent ball and seat closing interfaces to ANSI/FCI 70-2 V and VI (optional) standards.

The spring-loaded seat is kept in close contact with the ball to ensure seal even at low pressure. This allows stable opening and closing torques over a wide range of temperatures and high pressure differences.

The combination of metal seat and graphite seal ensures fire resistance

Components of different materials are available for a variety of applications with temperatures up to 500ºC

The unique design of the trunnion mounting valve can also be used in dust environments

metal hard seal valve can provide a complete valve and actuator "combination" for dust, high speed and other special application environment

Hardened balls and seats can be used for longer periods of time in harsher applications, including grout, stock and other wear media

Optional ball surface hardening process. (For details, please go to page 2) Hard chrome plating, nickel coating, carbide, chromium carbide